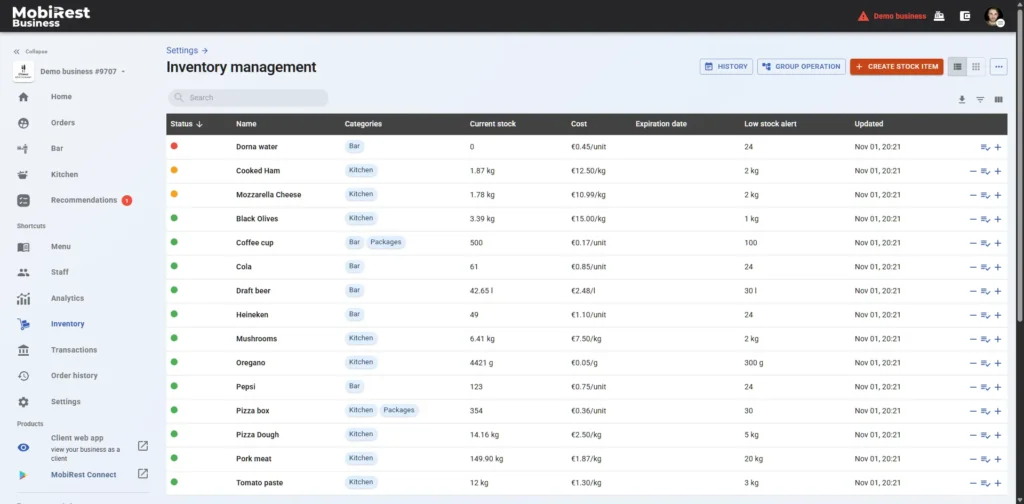

The inventory management feature provides real-time stock tracking, simplifying reordering and restocking.

To manage your stock entities, navigate to “Settings” > “Inventory“. (https://admin.mobirest.business/stock-management)

You can create stock entities for ingredients like “Mozzarella Cheese“, packaging like “Pizza Box“, or products like “Cola“.

Create stock item #

To create a stock entity, click the “Create stock item” button in the top right corner. Simply enter a name and specify the measurement unit, for example “kilogram”.

Editing stock items #

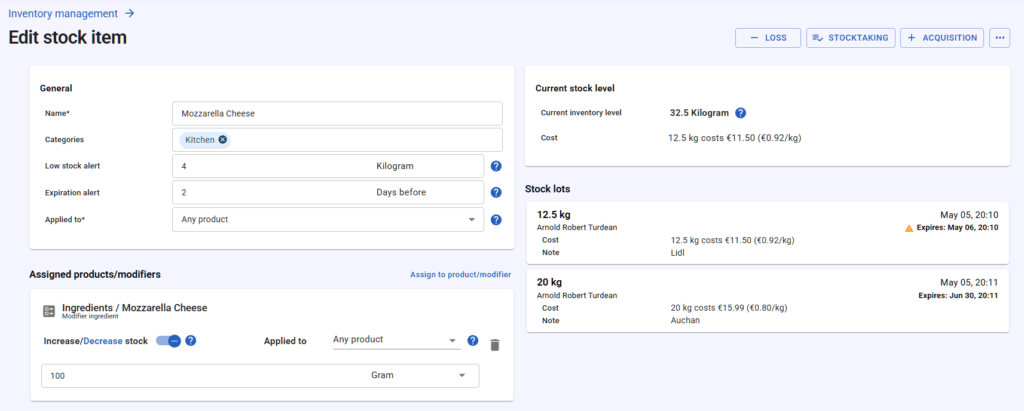

You can edit your stock items by simply clicking to them at the “Inventory management” screen.

Here you can configure your stock entity deeply.

- Name: You can update the stock entity’s name at any time.

- Categories: You can organize your stock items into categories helps streamline their management and day-to-day operations.

- Low stock alert: Optionally, configure a low stock alert. When stock falls below this level, all administrators receive an alert email, and affected products are marked as low stock for waiters to stay informed.

- Expiration alert: Optionally, you can set the number of days in advance the system will notify you before a stock lot reaches its expiration date.

- Applied to: Here you can select three option:

- Any product: Stock is updated every time the product is prepared.

- Packed products: Stock updates only when a packed product is prepared, useful for tracking packaging materials.

- Non-packed products: Stock updates only when a non-packed product is prepared. For example, if you use different coffee cups for takeaway and dine-in coffees, you can add both as ingredients—one as packed and the other as non-packed.

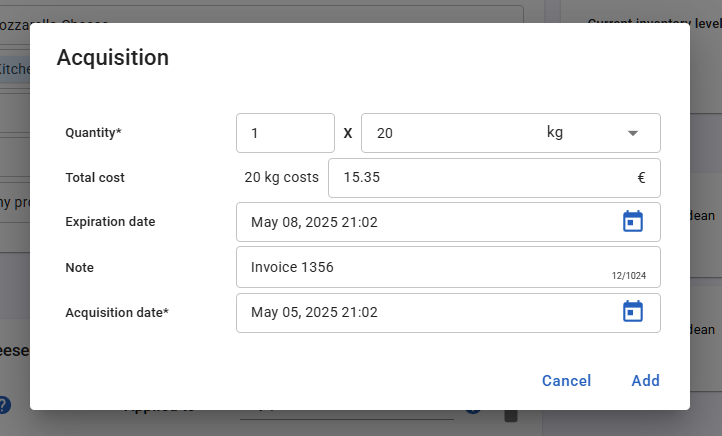

Acquisition #

This operation allows you to record new inventory purchases by specifying the purchased quantity and date. You can also optionally include additional details such as

- Total cost: If configured, the system uses this data to calculate the cost of products and modifiers, integrating it into business statistics, such as profit calculations.

- Expiration date: If this is set the system will notify you in time before your stock lots are expired.

- Note: Add an informal note for the purchase which can help you in the future, for example the purchase’s invoice number.

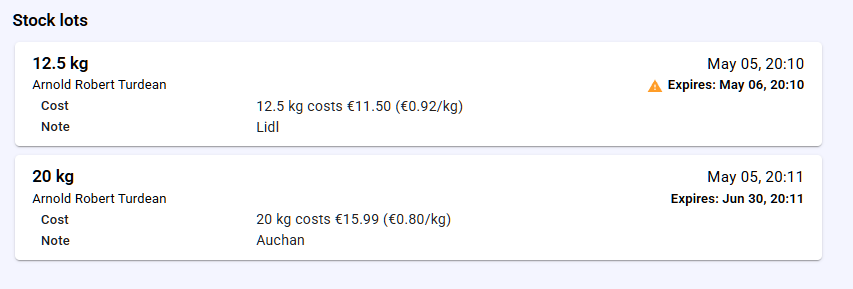

After you confirmed the acquisition a new stock lot will appear on the stock item’s page with the configured data. You can also update the details of your stock lots by simply clicking to them.

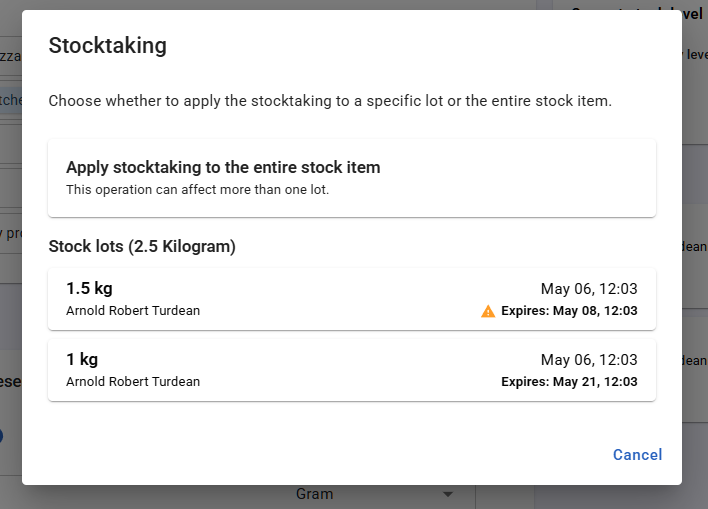

Stocktaking #

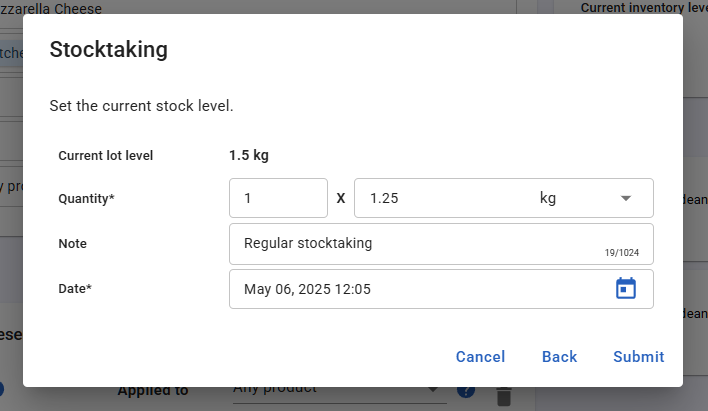

The Stocktaking operation lets you update and verify current inventory levels by manually entering the actual quantities in stock, ensuring accuracy between recorded and physical stock.

When you perform the stocktaking operation you can decide to set the current inventory level for the entire stock item or more accuretly for a particular stock lot.

Then you just need to mention your current physical inventory level, optionally add a note for the stocktaking and submit it.

Stock loss #

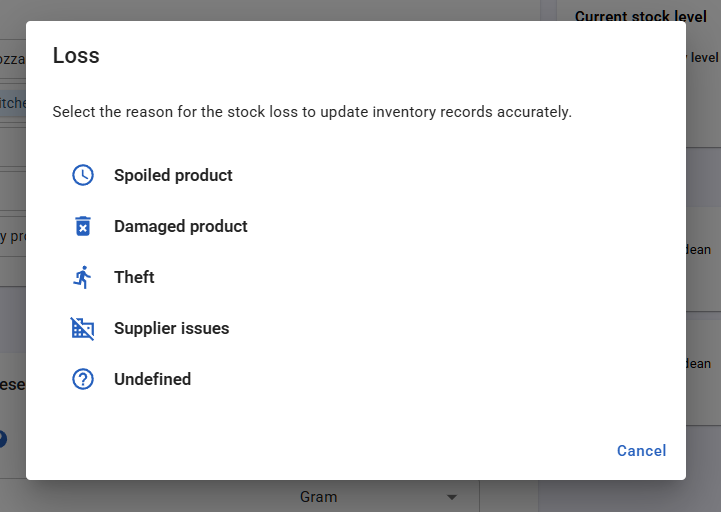

You can use the loss operation to record stock losses, allowing users to track them later. As the first step, select the loss reason which can be one of the followings: spoiled product, damaged product, theft, supplier issues or undefined.

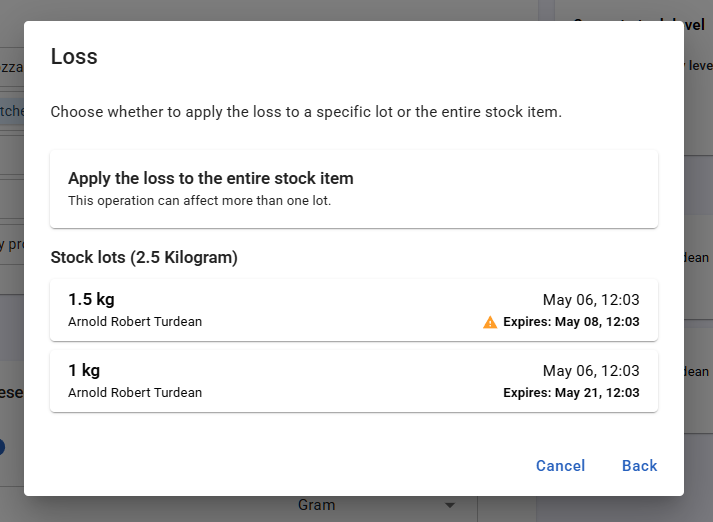

Then choose whether to apply the loss to the entire stock item or to a specific lot.

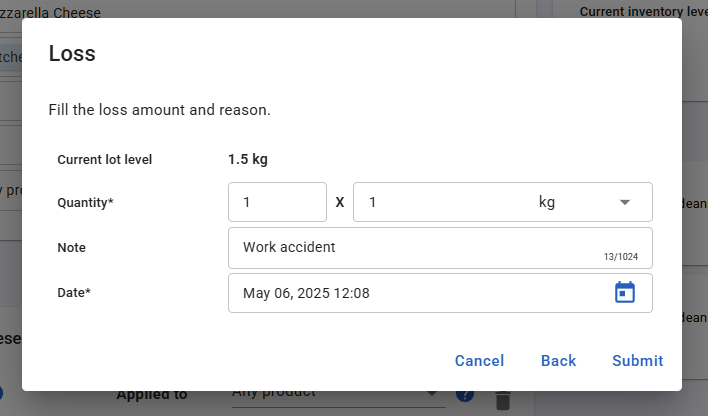

Finally, enter the loss quantity and optionally add a note.

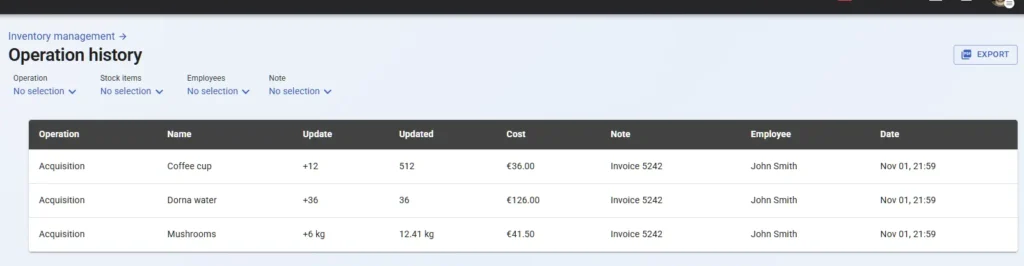

Operation history #

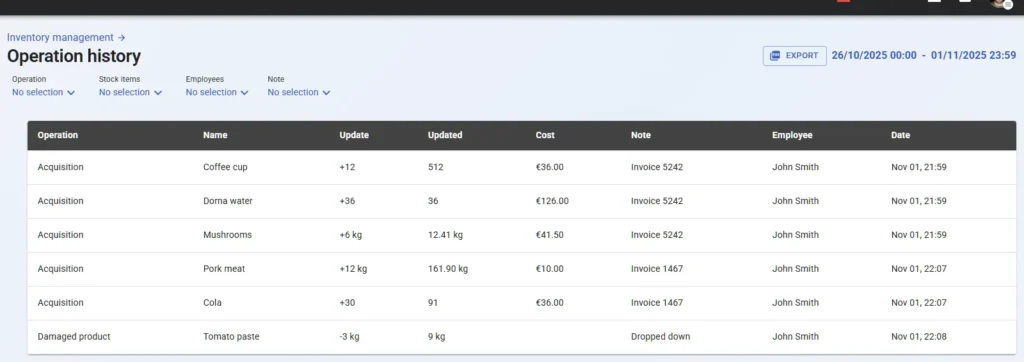

On the stock operation history page, you can view all past stock operations and filter them by various criteria such as date range, operation type, stock items, employees, and even notes.

You can also export the filtered operation list as a PDF by clicking the ‘Export’ button.

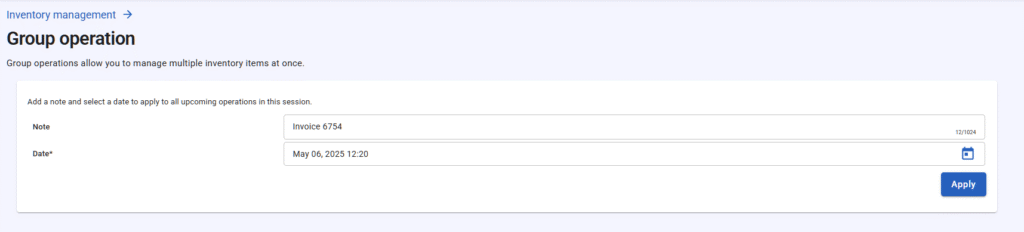

Group operation #

The group operation feature lets you perform multiple stock actions—like acquisition, stocktaking, or recording losses—quickly and all at once.

Optionally, you can add a note that will automatically apply to all upcoming operations. Then, select the operation date—such as the invoice date for an acquisition—and click Apply.

You can then carry out operations for individual stock items without needing to enter the operation date and note for each one separately.

Finally, click the ‘View Results’ button to see the outcome of the group operation. You’ll only see the updated stock items with all the relevant data like the performed operation, the quantity update, the item’s final quantity, etc.

You can also export the results of the group operation as a PDF by clicking the ‘Export’ button.

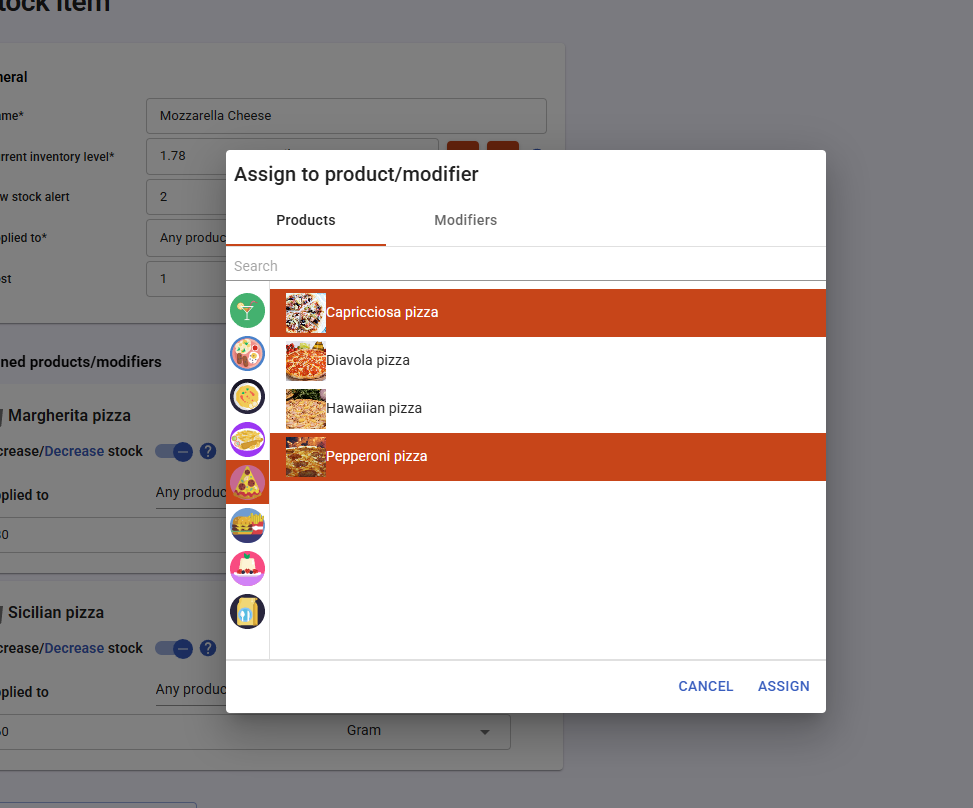

Assign the stock items to products and modifiers #

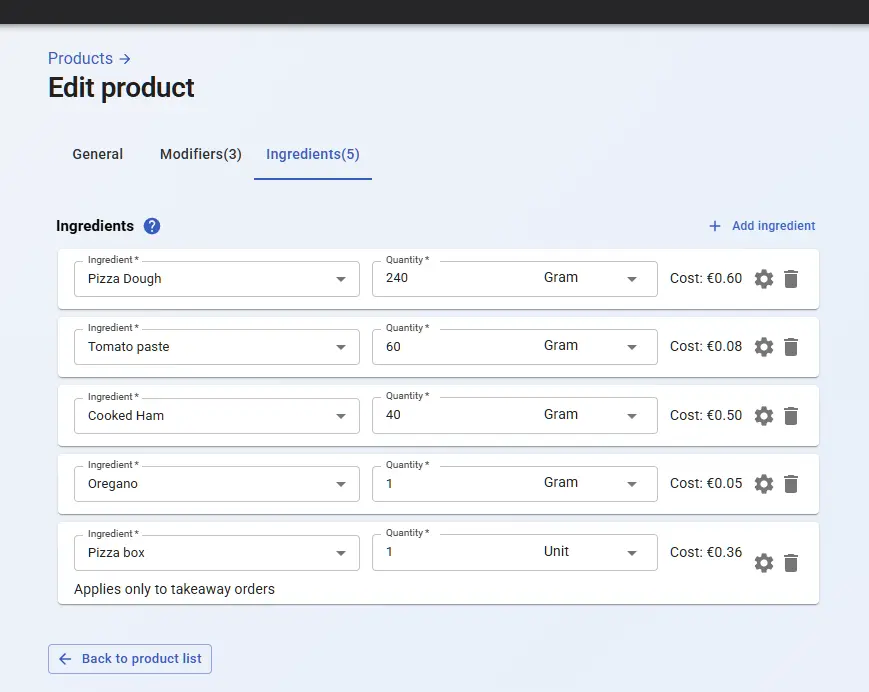

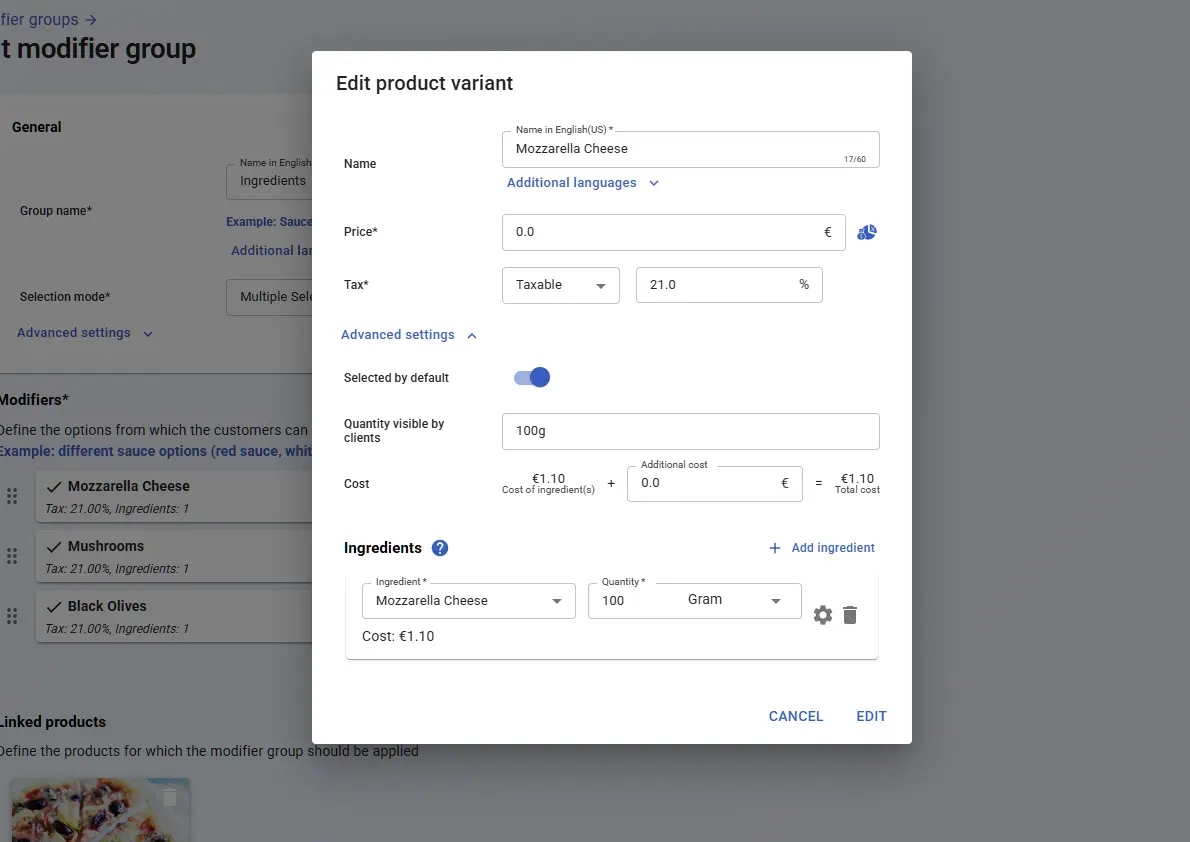

You can assign stock items as ingredients to both products and modifiers. When a product or modifier is prepared, the system automatically updates stock levels to ensure accurate tracking.

You can link stock items to products or modifiers from either the stock item’s page or the product/modifier’s page. The procedure is the same in each case.

To assign a stock item to products or modifiers, click the “Assign to product/modifier” button on the stock item’s page, then select the products or modifiers that require the stock item, then click to the “Assign” button.

After adding the related products and modifiers, you can define the quantity of stock used by each. For example, preparing a Margherita pizza requires 100g of mozzarella cheese, while a Capricciosa pizza needs only 70g.

You can also configure various advanced options for each ingredient, including the “Increase/Decrease stock” and “Applied to” settings.

You can also configure the ingredients for products and modifiers directly from their respective pages, the procedure is mostly identical.